Purchasing Office in USA!

For USA brands, Direct shipping from USA to worldwide destination!

Product Detail

Watson Mcdaniel TD600S Thermodynamic Steam Trap

Category:

▶ Watson Mcdaniel

keyWord:

Watson Mcdaniel TD600S Thermodynamic Steam Trap

Describe:

TD600S Thermodynamic Steam Trap

Contact us

Description

http://www.jinstartech.com/

General Attributes:

WATSON MCDANIEL THERMODYNAMIC STEAM TRAP Very good price

TD600S - Non-Repairable with Strainer

DRIP, TRACING: The TD600S is Non-Repairable and commonly used as a drip trap on steam mains and steam supply lines. Supplied with integral strainer and optional blowdown valve to protect trap from contamination. Ideal for outdoor applications that are subject to freezing and for super heated steam conditions.

The TD600LS is Reduced Size Discharge Orifice holes which are preferable in terms of performance, longevity, and efficiency; particularly on pressure over 150 psi

Product Overview

DRIP, TRACING: TD600S model steam traps with integral strainer are most commonly used in drip applications, such as draining condensate from steam mains and steam supply lines. They can also be used for steam tracing applications. These traps are suitable for outdoor applications that are subject to freezing as well as superheated steam conditions. They are compact and rugged with only a single moving part. Integral strainer protects against dirt and scale. If a fully in-line repairable design is required, the TD700S or the UTD450 with Universal QuickChange Connector is recommended.

Features

• Integral strainer with optional blowdown valve to protect trap from contamination

• High pressure applications up to 600 PSIG

• Hardened stainless steel seat and disc for extended service life even at high pressure

• Single trap will operate over the entire pressure range of 3.5-600 PSIG (recommended above 30 PSIG)

• Suitable for superheated steam

• Freezeproof when trap is piped in a vertical orientation for complete drainage of condensate

• Three-hole balanced discharge extends life of the seat area

• Trap will function in any orientation (horizontal preferred)

How It Works

The disc is the only moving part inside a thermodynamic trap. When steam enters the trap, it creates an internal pressure above the disc that instantly forces the disc to close tightly on the seat, preventing the steam from escaping. The internal steam pressure (holding the disc and seat shut) eventually drops, and the trap re-opens. When condensate enters the trap, it pushes the disc upwards, allowing the condensate to freely discharge. If steam is present, the trap instantly shuts.

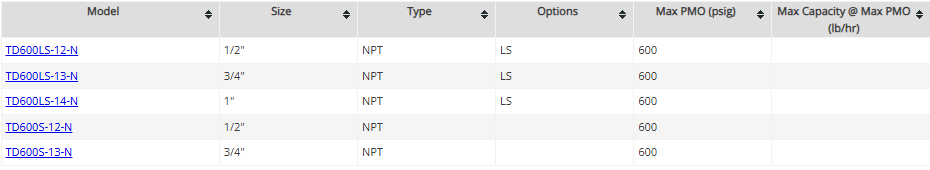

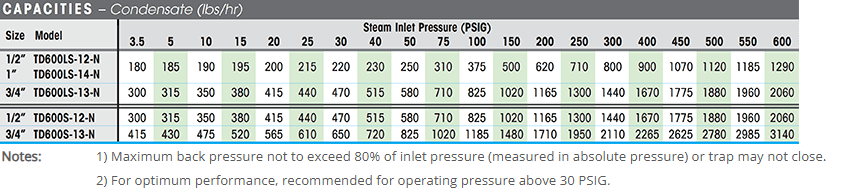

Selection / Sizing / Capacities

The TD600LS has reduced size discharge orifice holes which are preferable in terms of performance, longevity, and efficiency; particularly on pressures over 150 psi. For most drip applications the 1/2” TD600LS should have sufficient capacity. For higher load drip applications or if a 3/4” pipe connection is required, use 3/4” TD600LS for best results. Choosing a model with a condensate handling capacity in the range of the specific application will prolong trap life.

L = Reduced Size Discharge Orifice holes which are preferable in terms of performance, longevity, and efficiency; particularly on pressures over 150 psi.

Example:

Select working pressure; follow column down to correct capacity (lbs/hr) block.

Application: 500 lbs/hr at 100 PSIG working inlet pressure

Size/Model: 3/4” TD600LS-13-N

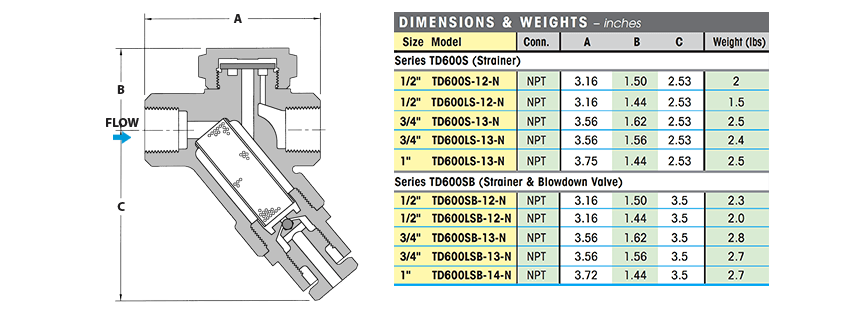

Dimension and Weights

Options

An insulation cap is available to reduce cycle rates and steam loss in rain, snow, or cold environments. Blowdown valve, used for flushing dirt and scale from strainer.

Installation and Maintenance

The TD600S can be installed in any orientation; however, horizontal with cap facing upward is preferred for longest service life. The one piece Body-Seat design is extremely simple and economical; however, this configuration is generally considered non-repairable since the seat cannot be replaced if damaged or worn. Welding of trap body directly into pipeline is not recommended since excessive heat can cause distortion of the seat area. All models of the TD600S contain an integral strainer for protection against dirt and scale. If a fully in-line repairable design or a trap that can be welded into pipeline is desired, the TD700S, TD900S or the UTD450 with Universal Quick-Change connectors is recommended.

Sample Specification

The steam trap shall be all stainless steel thermodynamic type with hardened integral seat and disc with integral strainer and blowdown valve.

Related products