Purchasing Office in USA!

For USA brands, Direct shipping from USA to worldwide destination!

Product Detail

Robotic/Automatic Tool Changers QC-1 Tool,9120-001T-000-000

Category:

▶ ATI-IA

keyWord:

Robotic/Automatic Tool Changers QC-1 Tool,9120-001T-000-000

Describe:

9120-001T-000-000

Contact us

Description

http://www.jinstartech.com/

General Attributes:

ATI-IA Robotic/Automatic Tool Changers very good price

Product Description and Features

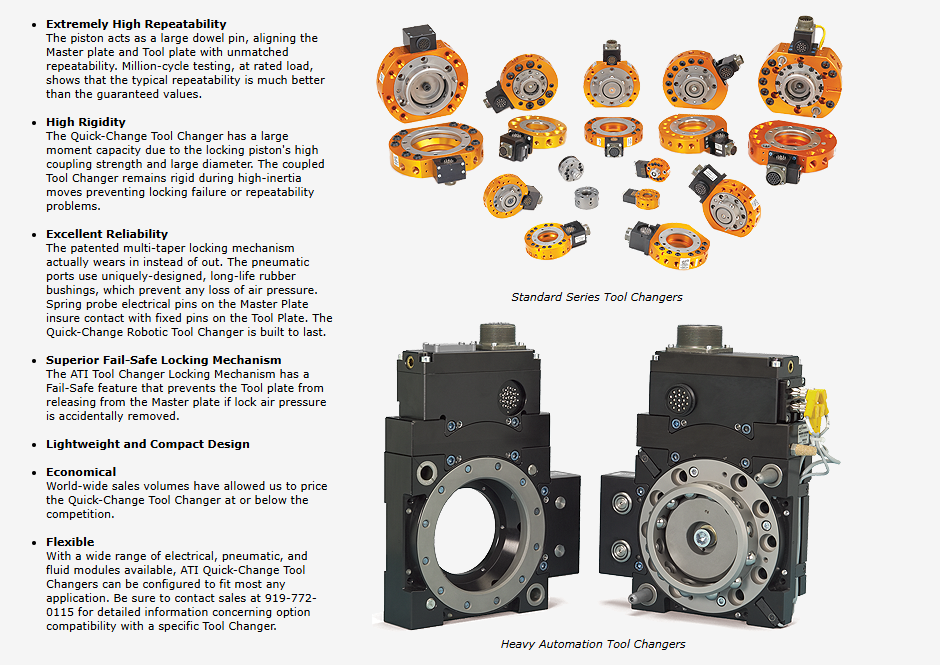

Standard Quick Change Tool Changers - This series of Tool Changers is built around a 'round' body with integrated pneumatic ports and our patented high-strength locking mechanism. A variety of electrical modules are available for use with the Standard Series.

Heavy Automation Quick Change Tool Changers - The Heavy Automation Series of Tool Changers is built around a 'square' body and uses our patented high-strength locking mechanism. This series of Tool Changers is more modular in design, with a wide variety of electrical, pneumatic, fluid, and high-power modules available. Heavy Automation Tool Changers are commonly used in heavy material handling and primary and secondary welding applications.

For applications that do not require a locking mechanism, ATI Utility Couplers may be an option.

If you are needing to change tools by hand, ATI Manual Tool Changers may be a cost-effective solution.

Both options can utilize a variety of ATI Tool Changer Utility Modules.

QC-1,PN#9120-001T-000-000

| Product Advantages |

|

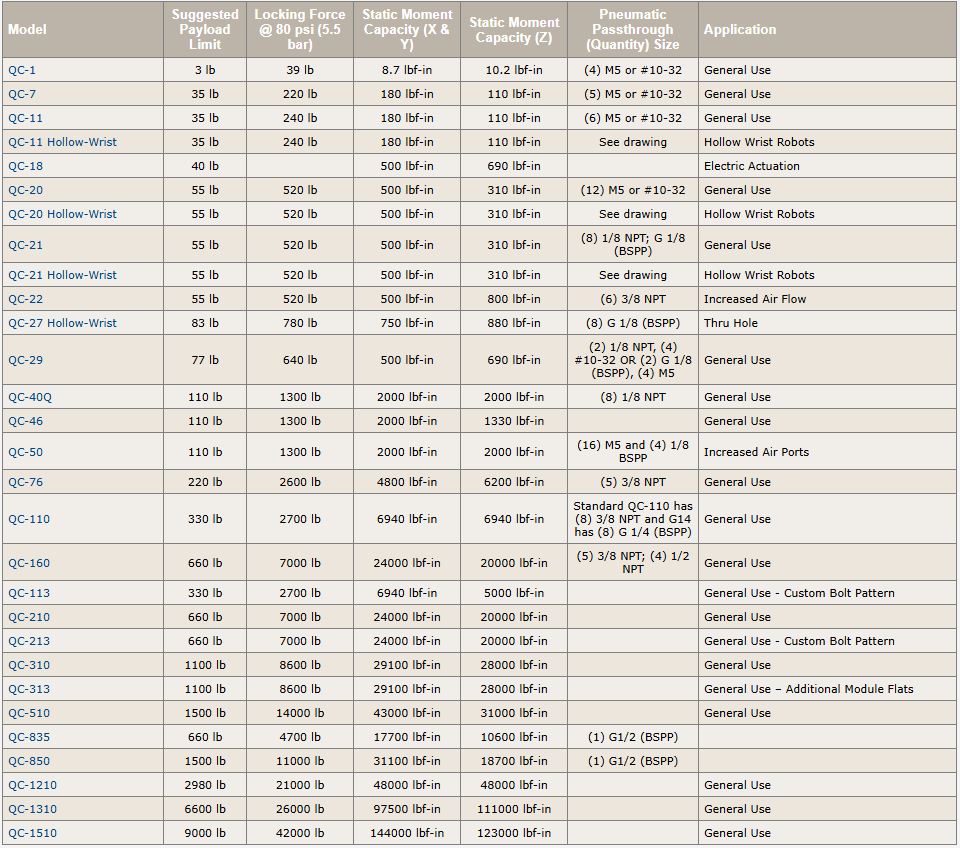

Specifications

| Suggested Payload Limit: | 3 lb |

| Locking Force @ 80 psi (5.5 bar): | 39 lb |

| Static Moment Capacity (X & Y): | 8.7 lbf-in |

| Static Moment Capacity (Z): | 10.2 lbf-in |

| Positional Repeatability - (X, Y, & Z): | 0.0004 in |

| Weight - when coupled: | 0.207 lb |

| Master Weight: | 0.124 lb |

| Tool Weight: | 0.0829 lb |

| Maximum distance between Master & Tool plate before locking at 87 psi (6 bar): | 0.04 in |

| Pneumatic Pass-through Ports (qty) Size: | (4) M5 or #10-32 |

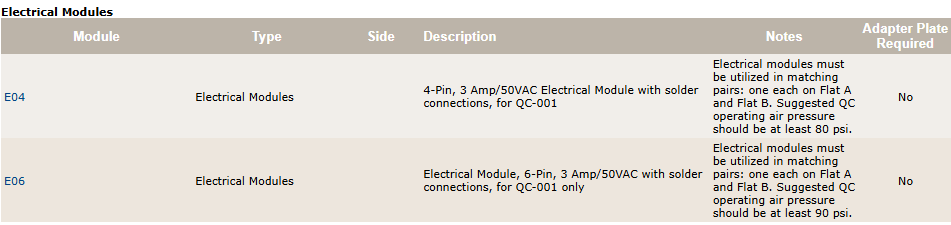

Compatible Modules

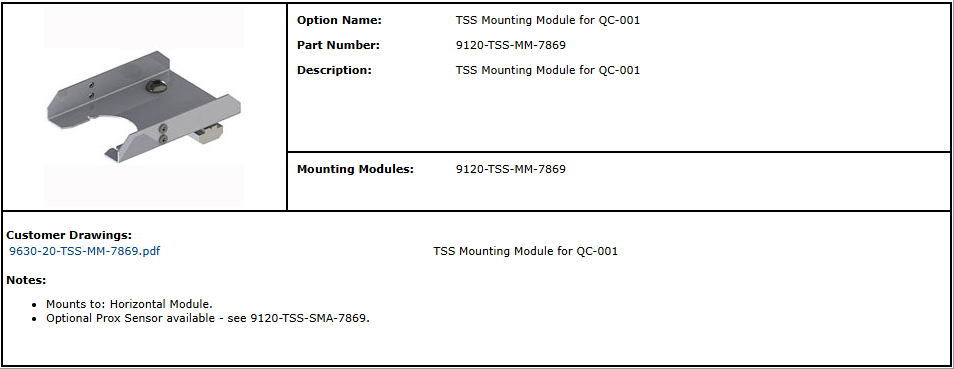

Tool Stand Options

Related products